Ideas & Solutions

Materials for High-Speed Digital and RF Applications: RF-35 and TPG-35

A low and stable dielectric constant (Dk<=3.5) enables the use of (ultra) thin base materials for fast clocking speeds and increased packaging densities at current impedance levels. It is the low dielectric loss however, which turns high-speed digital into a success story: Signal traces can become longer, and power input can be reduced - both at improved signal integrity. Teflon™/glass fabric base materials can be laminated together with FR4 prepregs and FR4 inner layers for mixed dielectric multilayers. High-speed digital printed circuit boards are typically large-sized high-layer count multilayers. Until recently the unavailability of ultra-thin laminates and prepregs prevented single-component constructions. However Taconic RF-35P (Dk=3.5) is a proven technological advancement which enables the manufacture of thinnest inner layers down to 50 micron (0.05 mm) thickness in production quantities. Based on this technology TacPrepreg TPG-35 (Dk=3.5), TPG- prepregs have been developed by Taconic which makes it possible to produce high-speed multilayer printed circuit boards with stable quality and smaller PCB thickness.

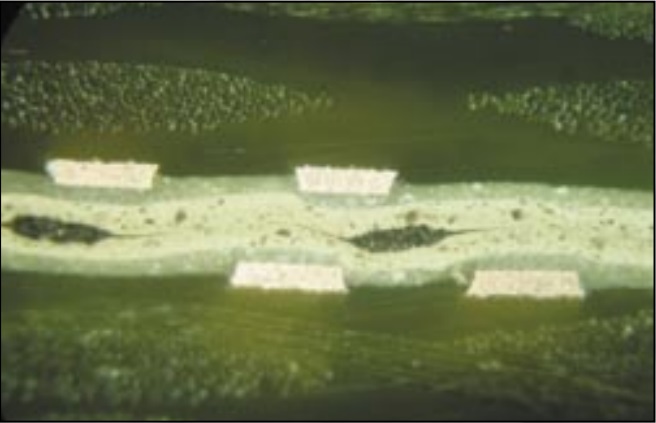

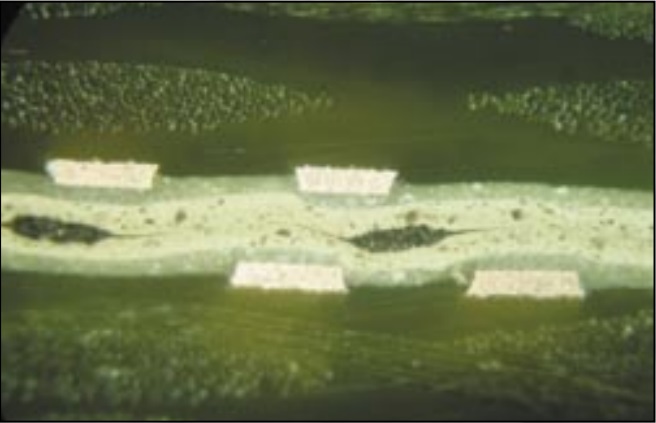

The picture below shows TPG-30 prepreg bonding together two FR-4 cores, each with 1 oz copper. This stackup provides very predictable dielectric spacing due to PTFE-fiberglass layer.

- The spec. details for RF-35P material you can find here.

- See datasheet for RF prepregs from Taconic - TacPreg TPG